Reliable evaluation

These testing methods are highly sensitive to small defects and provide an immediate test result

Reliable evaluation

These testing methods are highly sensitive to small defects and provide an immediate test result

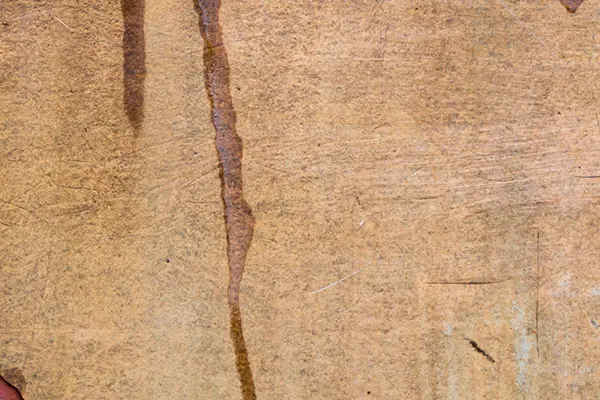

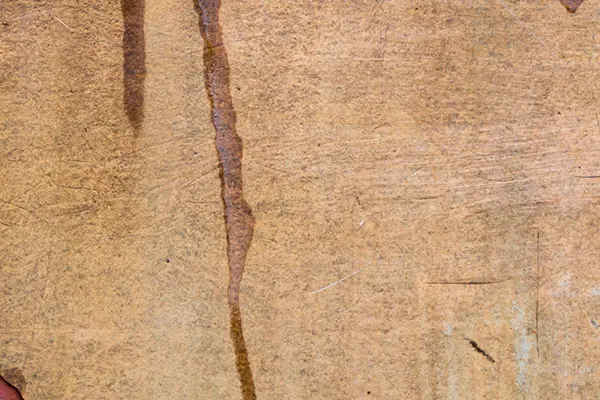

Crack Indication

Well-trained and experienced technicians.

Distinctive to these testing methods is that they have a high sensitivity to small defects and provide an immediate test result. DEKRA has well-trained and experienced technicians who can carry out testing and evaluate the results in a reliable way.

Magnetic Powder Testing (MT)

Testing is performed by inducing a magnetic field in a test object, for example with a magnet yoke, while an iron powder is applied to the surface. If there is a crack in the object, the powder collects around it and makes the crack visible.

Limitations:

- Material type (ferromagnetic materials only)

- Limited inspection depth (mainly surface defects)

- Surface quality (max. paint thickness: 50µm)

- References - standards necessary to judge the result

Penetrant Testing (PT)

A colored liquid (penetrant) is applied to the surface of the object. After some time the surface is wiped off and developer is applied to the surface. The developer makes color that has penetrated into any cracks visible, that is, indicates the crack.

Limitations:

- Temperature sensitive

- Errors below the surface are not indicated

- Cleaning process, surface condition and surface treatment

Eddy Current Testing (ET)

The test is performed by a magnetic field inducing eddy currents in the test object. Defects (cracks) cause disturbances of the eddy current and cracks can then be detected. With ET testing, defects can also be found on painted objects.

Limitations:

- Only usable on electrically conductive materials

- Delaminations parallel to the surface are difficult to detect

- Uneven and raw surfaces can affect the result

- Limited inspection depth